Gloves

WORK

IMPACT RESISTANT

CUT RESISTANT

Technical Information

Dipped Material

Nitrile

Nitrile is a multi-purpose dipped material that provides superior puncture and tear resistance as well as better durability. Nitrile offers good grip for oily and wet conditions and can perform in a wider range of temperatures than Polyurethane.

-

Foam Nitrile

Foam Nitrile

- Foam nitrile coating absorbs excess liquid from surfaces to keep gloves dry and provides a better grip. The coating offers a lighter feel and better dexterity compared to traditional nitrile.

- Milwaukee® Cut Level 3 Nitrile Dipped Gloves feature a foam nitrile coating for better grip.

-

Sandy Nitrile

- Sandy Nitrile has a lower soak through rate than foam nitrile, keeping hands dry. It provides longer life and has lower particulate shed for manufacturing, service work and remodeling applications.

- Milwaukee® Cut Level 1 Nitrile Dipped Gloves feature a sandy nitrile coating.

Polyurethane

Polyurethane is lighter weight and is more breathable giving it a barehand feel. The dipped material offers superior dexterity and improved grip without the sticky feeling often associated with nitrile. Polyurethane has a low particulate shed which is important for manufacturing, service work and remodeling applications. It also resists oils and solvents, but it does not perform well in wet or hot conditions.

Polyurethane is lighter weight and is more breathable giving it a barehand feel. The dipped material offers superior dexterity and improved grip without the sticky feeling often associated with nitrile. Polyurethane has a low particulate shed which is important for manufacturing, service work and remodeling applications. It also resists oils and solvents, but it does not perform well in wet or hot conditions.

Milwaukee® offers cut level 2, 3 and 4 Polyurethane Dipped Gloves that provide better fit and better protection.

Latex

Latex is ideal for providing grip in wet conditions and will stay flexible in a wide range of temperatures. It does not perform as well with oily or abrasive materials.

Latex is ideal for providing grip in wet conditions and will stay flexible in a wide range of temperatures. It does not perform as well with oily or abrasive materials.

Milwaukee® Cut Level 1 and 3 Winter Insulated Gloves use latex for their performance in wet and cold temperatures.

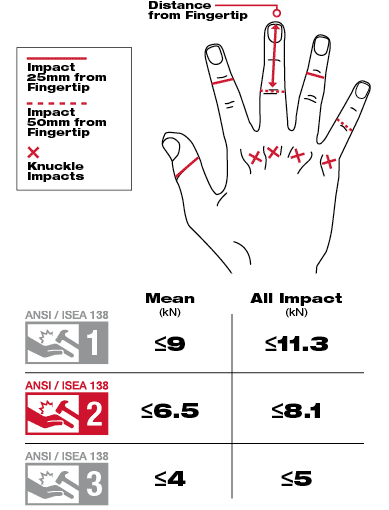

ANSI/ISEA 138 - Impact Resistance

There were 74,940 hand injuries in 2018 from being stuck by or against an object reported by the Bureau of Labor Statistics. In response to the large number of back of hand injuries, ANSI/ISEA provided a standard test method for impact resistance announced in 2019. The test classifies three levels of impact protection with 3 being the highest. This is different from the EN 388 test that notes impact as a pass/fail and only test knuckle location versus the full back of hand. The test is done by dropping a falling mass or “drop striker” on both the knuckles and the fingers/thumb. The anvil is dropped with a force of 5 joules. The knuckles are tested 4 times and the fingers/thumbs are tested 5 times. A higher impact rating is important for back of hand protection but often reduces dexterity and mobility. Understanding your intended applications and their potential associated risks is important when you are choosing a glove.

Milwaukee® offers a line of impact dipped, leather and demolition gloves that are all rated at a level 2 for back of hand protection while still maintaining dexterity and mobility.

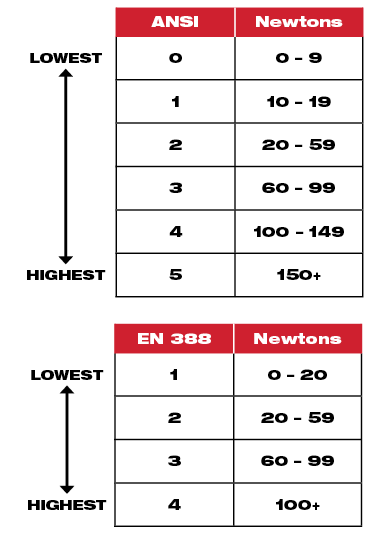

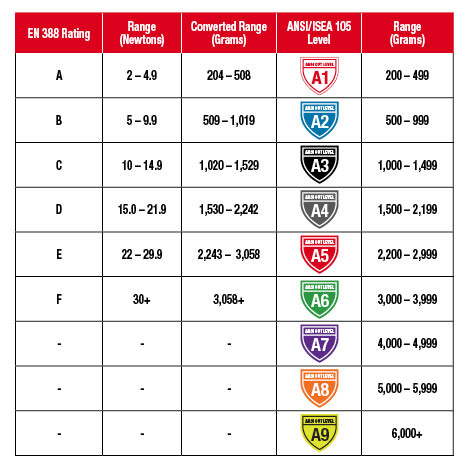

ANSI/ISEA 105 - Hand Protection

In 2018 the Bureau of Labor Statistics reported 63,830 injuries from cuts, lacerations or punctures and found that the median days away from work from a hand injury was 6. ANSI/ISEA 105 is the American National Standard for hand protection classifications that regulates how gloves are tested and rated for different levels of cut resistance. Updated in 2016 from 1-5 to A1-A9 the higher number indicates greater cut resistance or more technically that it can withstand more grams of force.

Milwaukee® offers gloves in a range of A1-A9 to handle a wide range of applications.

Cut Rating

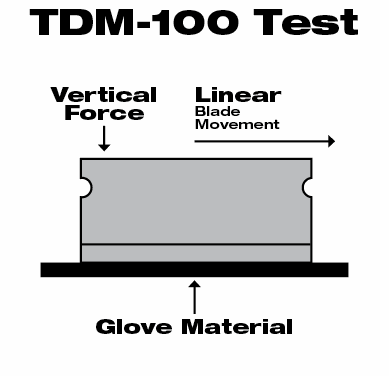

ASTM F2292-15 - TDM-100 Test

The ANSI/ISEA 105 test is now only performed with a machine called a tomodynamometer or TDM, which is why the test is also referred to as the TDM-100 test. The samples are cut 20mm in a straight path using a straight-edged blade and different loads of force. The material is cut five times with three different loads. Using the average, the test provides the cut score of A1-A9.

Mechanical Risk

Both the EN388 and the ANSI/ISEA 105 standards test for mechanical risks denoted as abrasion, cut, tear and puncture resistance. Starting in 2019, ANSI/ISEA now has an additional test for impact protection for back of hand protection. The standard establishes performance requirements for the knuckles and fingers.

Puncture Resistance

- Blunt Probe - ANSI/ISEA 105 and EN 388 use similar methods to test for puncture resistance. The standard uses a 4.5mm diameter steel probe with a round point at a speed of 100mm/min to penetrate the sample at a 90-degree angle. This is done 12 times and an average of the maximum force exerted on the prob is used to determine the performance of the glove. The ANSI scale is 0-5 with 5 being the highest protection against puncture. The EN 388 test is the same method but is between 1-4 with 4 being the highest.

- Hypodermic Needle – This standard is also referred to as ASTM F2878-10. It measures the gloves puncture protection by using a 25-gauge hypodermic needle to puncture the glove at different forces. Levels between 0-5 correspond to how well the glove resisted puncturing with a higher rating denoting more puncture protection.

Abrasion Resistance

There are two different abrasion tests depending on if the glove is coated or uncoated. ASTM D3389-10 is used for coated gloves and the test is suspended once the film or coating is worn through. ASTM D3884-09 is used on uncoated gloves and the fail point is when the first thread or yarn breaks. Both tests are done by rubbing an abrasive material on the glove to measure protection from rough surfaces. The number of cycles the glove can withstand before failing corresponds to a rating between 0-6, 6 being the best for abrasion protection. Levels 0-3 are tested with a 500-gram load and levels 4-6 are tested at a 1,000-gram load

EN 388 - Hand Protection

EN 388 is the European standard for hand protection and includes cut resistance, abrasion resistance, tear strength, puncture resistance and impact protection.

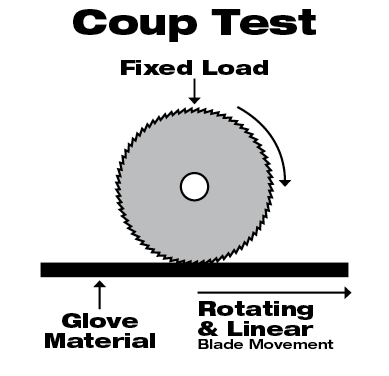

Coup Test

Tested using a rotating blade with a fixed load to determine a cut rating between 1-5. If the blade makes 60 passes without cutting the material than it moves to the ISO 13997 or TDM test. The Coup Test can sometime fail with a highly cut resistant material because it dulls the blade and does not produce results. It is more frequently used for lower cut resistant materials. If it provides a 3 or above it is marked as an “X” for not applicable.

ISO 13997 - TDM-100 Test

The same TDM-100 used in the ANSI/ISEA 105 test is used here when results are not possible in a coupe test. The test is performed in the same manner as the ANSI/ISEA standard however, the load forces are in newtons instead of grams. The ratings are shown between A-F. It is the highest newtons of force on the scale. The standard testing procedure offers a more accurate comparison with the ANSI/ISEA 105 standard.

Mechanical Risks

Mechanical risks are tested in both the ANSI/ISEA 105 standard and the EN 388 standard. They are abrasion, cut, tear, puncture and impact resistance. Cut testing includes both the Coupe and ISO 13997 test.

- Abrasion – Sandpaper is applied to the sample under a standard pressure. The rating is awarded based on the number of turns needed before a hole appears in the material. The abrasion rating is between 1-4. A rating of 4 denotes a higher level of abrasion protection compared to a 1.

- Tear - A materials tearing strength is tested by measuring the force material required to tear the sample apart. The rating is between 1-4. A rating of 4 denotes a higher level of tear protection compared to a 1.

- Puncture – The puncture test is the same as the ANSI/ISEA 150 method but is out of a scale of 1-4 instead of 0-5. The test method is detailed under blunt probe section of ANSI/ISEA mechanical risks.

- Impact Protection – Unlike the other mechanical risk test impact protection for EN 388 is a pass/fail. It is test by cutting open the glove, lying it flat and placing it on top of a sensor. The glove is struck with 2.5kgs of force at a distance that provides 5J of impact energy. If the average force transmitted is less than or equal to 7kN and no single result is greater than 9kN it receives a pass rating or “P”. If it failed or was not tested it receives an “X”. Unlike the ANSI/ISEA 138 standard that test the full back of hand this only test the knuckle location.

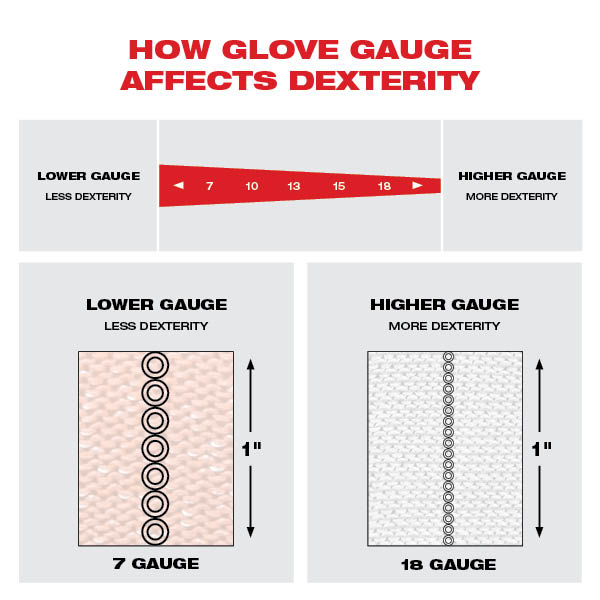

Gauge

The gauge of a glove refers to the number of stitches per inch of knit material. A lower gauge uses thicker yarn and creates a looser knit whereas a higher gauge uses thinner yarn that provides a tighter knit. Generally, a higher gauge provides better dexterity and more comfort. However, the type of yarn, dipped materials, and dip coverage all factor into the final fit and comfort of the glove.

Milwaukee® gloves prioritize high dexterity and comfort in their materials to help users perform on the jobsite and are offered in various knits ranging from 13 to 18-gauge.

Milwaukee® High-Dexterity gloves are specifically designed with an 18-gauge knit to provide total hand mobility while still providing the same cut resistance as lower-gauge gloves of the same cut level rating.

EN511 - Protection From The Cold

EN 511 is the European test standard for evaluating protection from low temperatures. The standard applies to all gloves that provide hand protection from the cold down to -50 degrees Celsius. The test measures how well the glove can withstand convective cold, contact cold and water permeation. Milwaukee® Cut Rated Winter Insulated Gloves are EN511 rated to keep users protected even in cold environments.

Loading Results

© 2026 by Milwaukee Tool. All rights reserved.